*견적이나 기타 궁금하신 사항은 게시판을 이용해 주세요.^^

제품명 : BIOHAZARD Autoclaves SERIES

(250,310,450,610,680,840,1010,1500,2000,5145 LITERS),LABORATORY CARE

제조사 : TUTTNAUER / ISRAEL

-FEARURES-

In today’s society the need for safe bio-containment systems is increasingly

important. This is especially true in the sterilization process where standard

autoclaves cannot deal with the threat posed by harmful pathogens and other

contaminated materials that are emitted from BSL3/4 laboratories.

Tuttnauer is at the front lines, continuously creating new standards in the

field of bio containment. With years of experience in the market, Tuttnauer

produces reliable and safe bio- containment systems.

BSL Considerations

The Tuttnauer range of BSL autoclaves is designed to meet stringent Bio

Safety Level requirements for BSL3 and BSL4 facilities. These include a

hermetically sealed barrier between the different risk level zones and effective

sterilization and disposal of all effluent and gases.

Special autoclave design consideration is given to:

- Autoclave and piping components

- Biological seal (Bio-shield)

- Effluent sterilization cycle

- Filter sterilization

- Safety valves and expansion vessel

ADVANCED STERILIZATION CYCLES

Liquid Loads

Tuttnauer's laboratory sterilizers are designed for treating sensitve liquid

loads. The autoclaves ensure that the correct sterilization temperature is

attained when sterilization starts and that sterilization is initiated only when

a temperature probe placed inside the medium reaches the preset threshold

temperature. Tuttnauer offers advanced options that minimize the exposure time

of liquids to high temperatures thereby preventing over cooking without

compromising on sterilization results.

Fast Cooling

Accelerated chamber cooling is carefully controlled before chamber doors can

be opended preventing a sudden drop in chamber pressure and temperature that can

cause liquids to boil over. Tuttnauer’s accelerated cooling technology reduces

the number of cycles per day and protects the load by minimizing its exposure to

high temperatures. Rapid cooling typically reduces cooling time by as much as

75%.

Improved Air Removal

Effective steam prenetration of wrapped, porous and hollow loads is achieved

due to air removal prior to sterilzation by an efficient vacuum pump. The

post-vacuum drying phase ensures complete drying of porous loads and hollow

instruments, and guarantees that even the most difficult loads will easily reach

sterility assurance levels.

Advanced Sterilization Cycles

F0 Cycle

The "equivalent kill effect" F0 value is calculated during the heat-up phase

of a sterilization cycle thereby reducing total media exposure time.

Sterilization exposure time begins when the slowest-to-heat load temperature

sensor within the autoclave has reached a predetermined set temperature.

Streaming Steam Cycle

(105°C)

The streaming cycle is most commonly used for melting agar in Petri dishes.

It is a low temperature sanitation cycle set at 105°C. Steam is allowed to enter

the chamber and the fast exhaust valve is opened to allow steam to stream over

the contents of the unit.

Disinfection/Isothermal Cycle

(70-95°C)

A flexible low temperature cycle enables disinfection (“low” temperature

isothermal). Temperature range settings are flexible within 70°C - 95°C

range.

DOCUMENTATION AND MONITORING

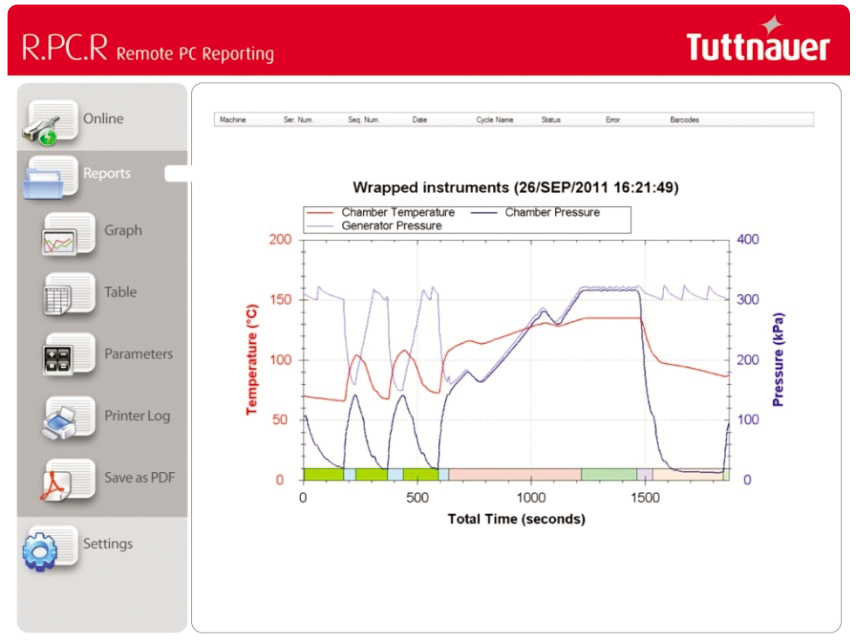

R.PC.R Software

Automatic Recording of Cycle Information to Your PC

Reporting You Can Rely On

- Automatic recording of cycle information to any PC on your network

- Convenient access to graphs and tables that are easy to understand

- Easily generate PDF reports

- No need to file printouts, saving you time

Be in Control with Real-Time Remote Monitoring

- See the real-time autoclave display on your PC

- Monitor all activity for up to 8 autoclaves

With R.PC.R you can see: Graphs of the

cycle data, Numeric cycle data, cycle print-outs, measured values table,

parameter table.

Note:

- R.PC.R monitoring feature is not available with Allen Bradley controller

Documentation Package

An optional full documentation package is available:

- Installation Qualification (IQ)

- Operation Qualification (OQ)

- Performance Qualification (PQ)

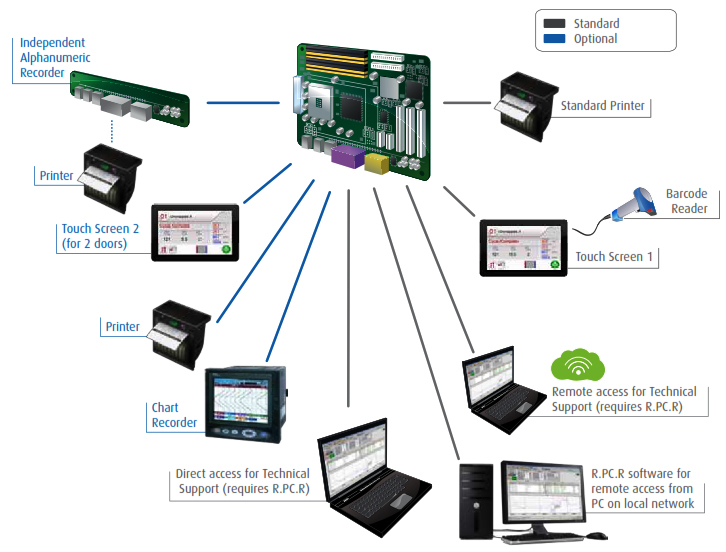

Controller Options

CONTROL SYSTEMS

Advanced Control System for Your

Laboratory

Take advantage of Tuttnauer’s sophisticated user-friendly control systems for

repeatable high performance.

Choose either Tuttnauer’s sophisticated Bacsoft

controller or the Allen-Bradley (AB 1400 PLC) controller.

Standard Features

- 7” Multi-color touch screen panel

- Keypad control panel on second door of two door autoclaves with Bacsoft

controller

- Stores the last 200 cycles in built-in memory (Bacsoft)

- Multiple access levels and user passwords to control access/operation of the

autoclave

- Diagnostic In/Out test (enables technician to check each system component

separately)

- Sterilization Temperature range 105°C to 138°C

- PID (Proportional Integral Differential) pressure control

- Filter replacement notifications

Optional Features

- 10” Multi-color touch screen

- Up to 8 different barcode readers

- Independent Recording for cross-checking cycle measurements

- Disinfection/Isothermal Temperature range from 70°C to 95°C

- F0 software control

- 21 CFR part 11

Sophisticated Touch Screen HMI

The HMI (Human Machine Interface) has been designed with the

following

considerations:

- Multi-color display for easier reading from a distance

- Multilingual (26 languages)

- Graphical display of Temperature and Pressure trend graphs

|